Products

XSG FLASH DRYER

It has more than 80 sets of processing devices and its annual production capacity can be more than 500 sets with over 30 categories.

零售价

$ 0

市场价

$ 0

Keywords: drying equipment | vacuum drying | oven

Category:

重量

0

库存

隐藏域元素占位

- Descriptions

- General Descriptions

- Application

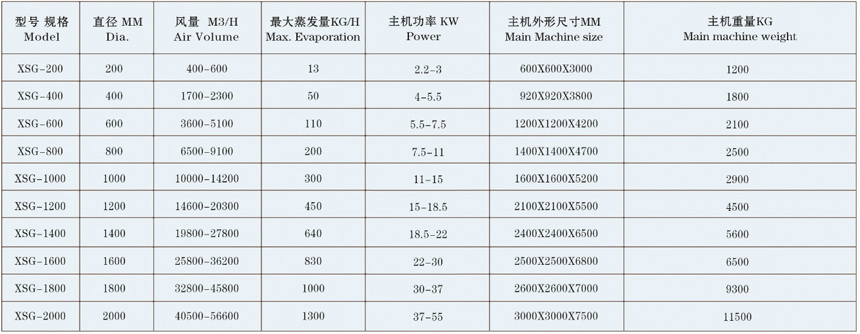

- Technical parameters

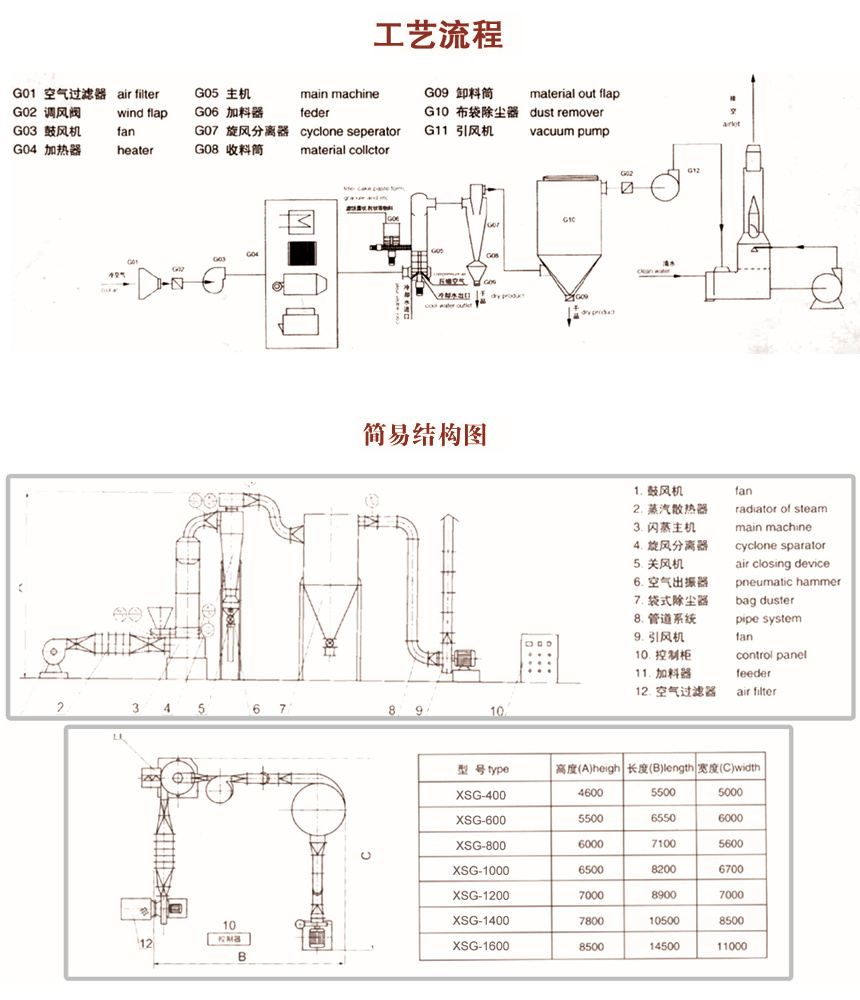

- Sketch map for inseallation

-

- Commodity name: XSG FLASH DRYER

- Commodity ID: 1046717011859431424

-

1, due to the material by centrifugation, shear, collision, friction and micro-granulation was highly dispersed state, and the relative speed of gas-solid two-phase, enhanced mass transfer heat transfer, so that the drying strength.

2, the drying gas into the bottom of the dryer, resulting in a strong rotating air flow, the material on the wall of a strong scouring with a role in the elimination of sticky wall phenomenon, suitable for viscous materials.

3, in the bottom of the dryer high temperature zone, heat-sensitive materials are not in direct contact with the hot surface, so that the material will not coke discoloration.

4, the upper part of the dryer ring can control the export of material size and humidity.

5, instant dry, drying time 1-5 seconds, the product is not overheating, uniform quality, good liquidity;

-

Working principle:

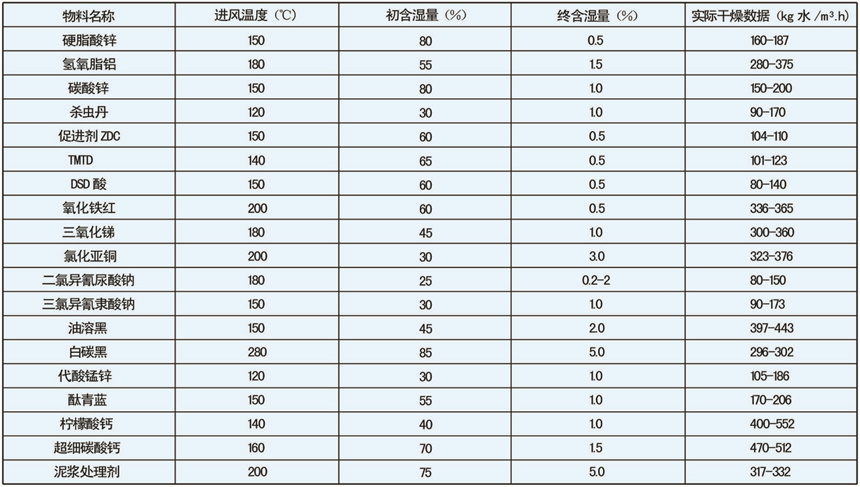

Rotary flash drying by the blower, radiator, feeding machine, flashing host, dust collector, induced draft fan and other equipment.

The wet feed is fed into the lower part of the drying chamber through the screw feeder, and the fresh air required by the dryer is heated into the tangential direction by the heater. The tangential hot air and the stirring mechanism form a strong airflow Vortex, material broken and quickly dried. The mixing mechanism at the bottom of the drying chamber strengthens the fluidization of the hot air in the drying chamber and pulverizes the still damp little pieces of material to increase the evaporation rate of the water; the rotary flash drying process is carried out by the mechanical rotation of the agitating mechanism and strong Hot aerodynamic interaction produces a rotating vulcanization drying process.

Under the action of rotating hot air, the particles are hot air entrainment to further dry; fine powder through the drying chamber at the top of the classification ring into the cyclone separator, the product was dried by the cyclone separator at the bottom of the automatic unloader; The large particles are blocked by the grading ring at the top of the drying chamber to return to the drying chamber and continue to be dried; the exhausted exhaust is discharged through the draft fan; the entire drying process is completed.

-

-

Recommended products

Message

Contact Us

ADD.: Dongqiao, Benniu Town, Xinbei District,Changzhou City, Jiangsu Province, China

General Manager: Yang Xiaorong

Mobile:+86 13506111605

Tel: 0086-519-89611808

Tel: 0086-519-83881918

Tel: 0086-519-89610828

Fax: 0086-519-83880970

E-mail: yang_xiaorong@aokaicz.com

E-mail: yxr1218@sina.com

Powered by: www.300.cn Changzhou | SEO